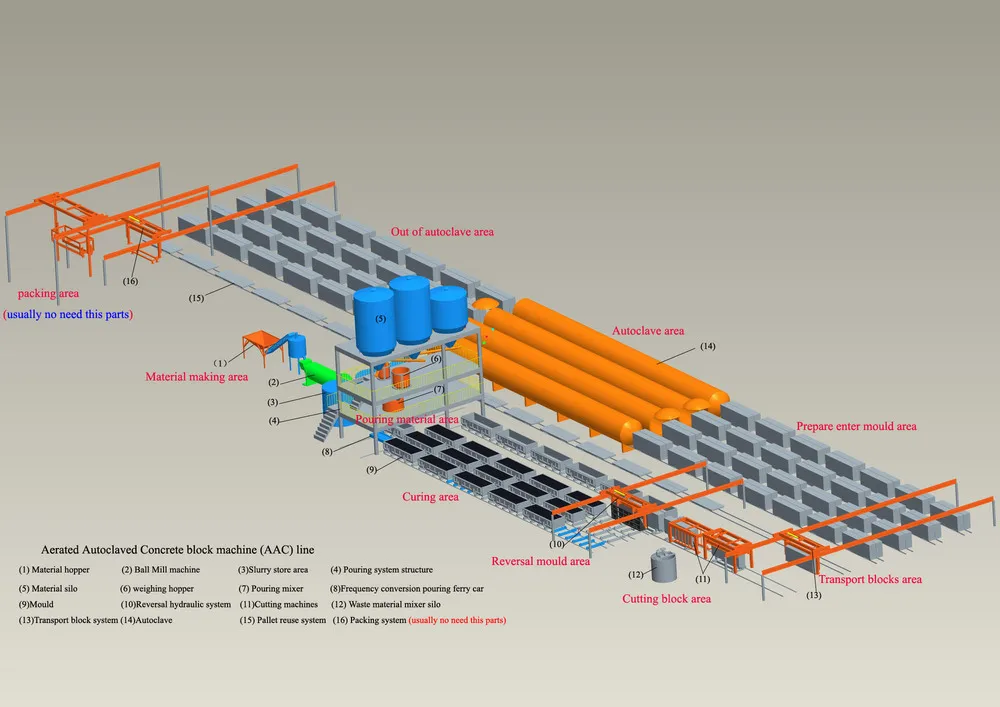

Brand Name: JIXIN

Model Number: AAC block production line

Place of Origin: Henan, China (Mainland)

1.Storing, supplying and processing of raw materials of AAC blocks.

1 Product weight is according to 600kg/m3 to control.

2 annual capacity 300,000M3.

3 set raw material proportion: cement 6.5%, raw lime 23%, fly ash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4 water and material rate 0.631

5 one mould product 2.88M3

6 Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7 casting slurry temperature 38-42 degree

8 body quiet stop. Time is 1.5-2.5hours, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9 Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

10.Cement lime fly ash style aerated block raw material proportion

waiting for using.Sacks of cement and bulk cements stored in cement warehouse.Chemicals and aluminum powder

are separately kept in chemical warehouse and aluminum warehouse.When used,these raw materials are carried into

workshop respectively.Quick lime is sent by vibrating feeder and belt conveyor into jaw crushers to smash. Smashed

lime is sent into lime silo by bucket elevator and then is transported into ball mills by screw conveyor. Fined materials

are sent into proportion bin by screw conveyor and bucket elevator.Aluminum powder is lifted by a truss motor to

second layer of batch planta and empty into mixer.

2.Aerated block Dosing, Stirring and Casting

Ground lime and cement is measured by lime and cement measuring tank.

All the measuring and dosing is in the batching center, controlled by PLC automatic controlling computer, to make

sure of continuity and accuracy in the process of dosing.Materials slurry is transported by screw conveyor into

mixer ,together with aluminum powder. Slurry temperature should reach about 40° -This is technical requirements.

If the actual temperature doesn’t arrive 40°,vapor is used in the measuring tank to raise temperature.

3.Setting,curing and foaming.

Materials slurry in the mould is transported to the place for setting,curing and foaming by ferry push car .When it is

conveyed to precuring room, room temperature should range from 50 to 70°.This period lasts one hour and a

half to two hours(If materials take on geographical advantages,this precuring can be eliminated) , then the slurry

approach the cutting intensity, which we call green blank.

4,Cutting and organizing into groups

Sling takes green blank to the cutting board together with the mould and the side plates. Turning over sling turns the

blank with 90 degrees in the air. After demoulding, it conveys the blank to the cutting car. The cutting car driven by

the motor runs slowly through the vertical cutting device, and runs to the horizontal cross-cutting device after vertical

cutting is finished. When the cart is stopped at the middle place of the horizontal cross-cutting device,cross cutting